DHSEAWORKS

TSHD Scelveringhe

Solid and Reliable

"The Scelveringhe"

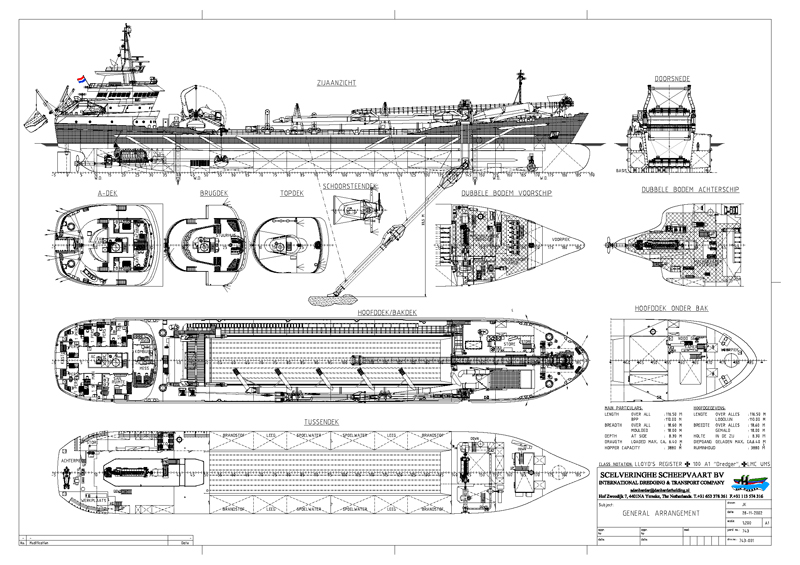

The trailing suction hopper dredger Scelveringhe was built in 2004 and has a hopper capacity of 4000 Mᶟ.

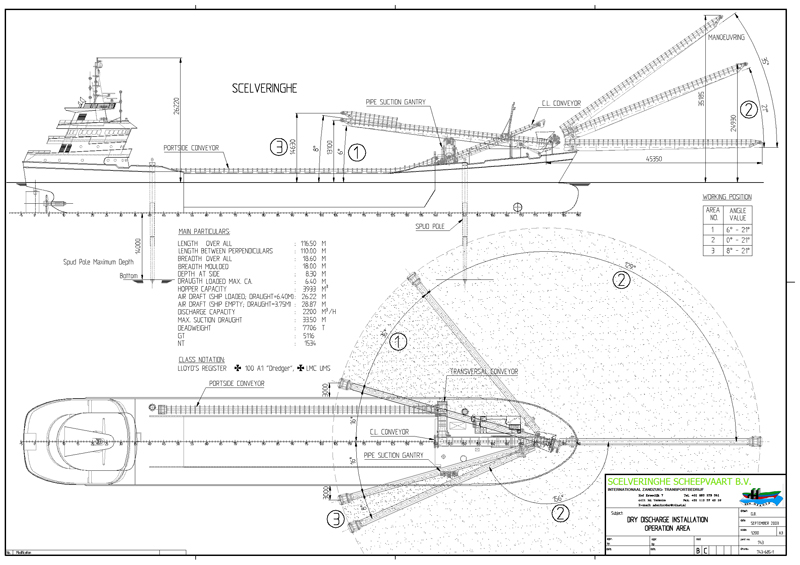

By using spud poles, mooring actions are minimised. Before and during unloading, the load is pumped dry using a vacuum installation. The unloading installation is developed and designed by years of experience and is capable unloading the vessel in an average of 2.5 hours. The vessel is equipped with a special designed hydraulic screening plant so we can produce products as requested by our customers.

The key to success of the company is based on the highly skilled crew

and the high standard of maintenance which improves the reliability of our fleet. They form the strength of the company.

Video

Specification

Type of vessel:

Vessel:

Single propeller trailer suction hopper dredger with single trailing suction pipe, dry unloading installation with grab crane and conveyor belts.

Year of construction

2004

Call sign

PGAA

Home port/flag

Yerseke, The Netherlands

Class:

Lloyd’s register >P100 Al ‘dredger’,

ri1LMC, UMS, self-discharging hopper dredger

Sailing areas

A1 & A2

Navigation/ safety equipment:

In accordance with class requirements and SI

Spud poles:

2x, telescopic, winch-operated

Dimensions:

Length overall:

116,83 m

Length between perpendiculars:

110,44 m

Beam:

18,60 m

Draught:

6,40 m

GT / NT:

5.116 GT/ 1.534 NT

Tank capacity:

Fuel tanks total:

607 m3

Lubricating oil tanks total:

50 m3

Hydraulic oil tanks total:

30 m3

Dredger installation:

Hopper capacity:

4.000 m3, deadweight 7.745 tons

Dredging depth :

approx. 35 meter

Dredge pump :

In-house design, driven by MAK diesel engine, type 6M25, 1,850 kW

Jet water pump:

Nijhuis 750 kW, cap. 2,600 m3/hour, 8 bar

Suction pipe/gantries

In-house design, diameter 850 mm, with cardan shaft, jet water pipe and draghead.

Gantries with winches and stabilizers.

Screenbox:

Hydraulically adjustable

Dry unloading installation:

HydraulicallHydraulic crane with a grab of

18 m3, movable over rails.

Conveyor belts electrically/hydraulically driven.

Engine room:

Main engine:

MAK diesel engine, type 9M32C, power 4,320 kW, Flender reduction gearbox, type GRCA759, reduction 600:178

Shaft generators:

1x Leroy Somer, driven by main engine, power 1,800 kW, at 600 rpm, 1x Leroy Somer, driven by the dredge pump motor, power 1,800 kW, at 720 rpm

Generator sets:

2x Caterpillar 3306, 190 kW/60 Hz

Bowthruster:

LIPS, 750kW electrically driven.